Micro Paving Slurry Seal Equipment 13m³

Microsurfacing Slurry Paver, Road Slurry Paving Machine, Micro Surfacing Paver. We are road pavement equipment manufacturer, offering asphalt emulsion spreading and sealing machinery

Micro Paving Slurry Seal Equipment 13m³

Microsurfacing Slurry Paver, Road Slurry Paving Machine, Micro Surfacing Paver. We are road pavement equipment manufacturer, offering asphalt emulsion spreading and sealing machinery

Gaoyuan is a road maintenance equipment manufacturer and this is one of our asphalt repair equipment. The micro surfacing paver HGY5312TFCS6 is mainly used to handle the pavement problems, such as reduced friction, cracks, and rutting. The paver uses HOWO chassis and adopts 310HP main engine, it has 13m³ aggregate bin and 4m³ asphalt emulsion tank. As a result, the micro surfacing paver is well for improving the friction and water resistance on the pavement, as well as increasing the pavement evenness.

Main Parameters

| Parameter | Standard Details |

| Chassis Series | Shaanxi Heavy Duty Automobile M3000 |

| Chassis Model | SX1319MC6 |

| Total Weight (t) | 31 |

| Chassis Engine Power (KW)( PS) | 276(375) |

| Emission Standard | National Standard Ⅵ (Standard Ⅲ, Ⅳ, V available) |

| Cab | New M3000 |

| Max. driving speed (km/h) | 80 |

| Min. driving speed (km/h) | ≤1 |

| Auxiliary Engine Power (KW)( PS) | 119(160) |

| Aggregate Bin Volume (m³) | 13 |

| Emulsion Tank Volume (m³) | 4 |

| Water Tank Volume (m³) | 4 |

| Addition Agent Tank Volume (L) | 400 |

| Stuffing Box Volume (m³) | 2×0.5 (2 feed bins) |

| Fiber Box Volume (m³) | 0.2 |

| Fiber Feed Speed (kg/min) | ≤3.5 |

| Output of Mixer (t/min) | ≤3.5 |

| Paving Width (m) | 2.5~4.3 |

| Paving Thickness (mm) | 3~15 |

| Dimension (mm)(L×W×H) | 11820×2500×3360 |

Main Features

- The high-end chassis manufactured by Shanxi Heavy Duty Automobile features low oil consumption and low emission for maximum economical and environmental benefits. Its outstanding stability provide the operator with comfortable driving experience.

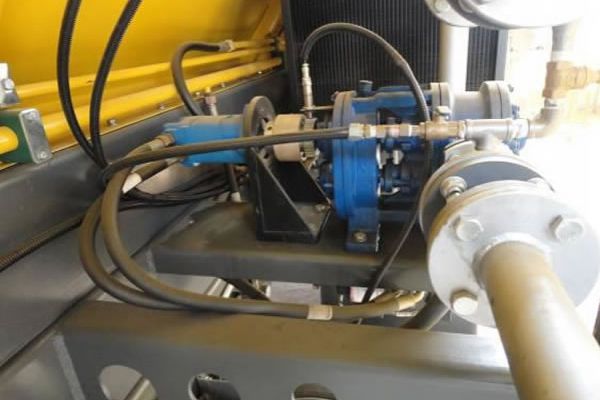

- The construction auxiliary engine features large power, low emission and stable performance.

- With a maximum mixing output of 3.5t/min, the slurry seal equipment is able to satisfy construction requirements of different paving widths, thicknesses and techniques.

- The slurry seal equipment is designed with high pressure and low pressure water washing device for easy equipment cleaning and maintenance.

- The aggregate bin features a large volume of 13m3 and the 55° inclined wall smoothens the aggregate discharge.

- Master controller and extended module are connected by CAN bus, flexibly arranging in the distribution box. With distributed bus architecture, the controller directly actuates the elements for great improvement of stability and consistency of electric system.

Chassis(HOWO)

- Low fuel consumption

- Low Emission

- Strong Power

- Comfortable and Convenient Driving

Work System

Examples

Related Products

Get in Touch